Scope Of Supply (spare parts & services)

What We Can Do For You

Bottling Line installation & Commissioning

We understand that the installation and commissioning phase of any project is the most critical. Utilizing our broad resources base, we select our trained technicians to conduct the installation & commissioning on the complete spectrum of machines constituting a bottling line across breweries, carbonated soft drink (CSD), juice and the diary industry.

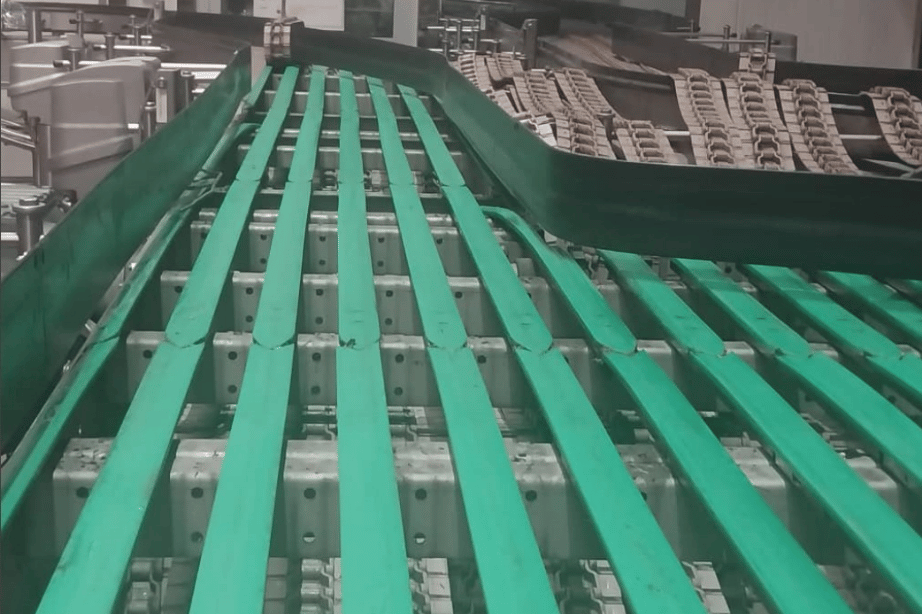

Conveyor Maintenance and Overhaul

Conveyor Maintenance Service is a great part of our business as to help customers take care of their own Conveyors. We are able to supply parts and on site fitting and welding services.

We have our own range of conveyor (chain & Belt) cleaners/scrapers that have been site proven to be second to none and great value.

We can arrange a preventative maintenance scheduled for your conveyor. Consistent care for your conveyor system reduces costly downtime and keeps your product moving smoothly.

Bottling Line Maintenance & Overhaul

Moz Eng. Service Ltd. offers overhaul services for your machines even when your machines have stopped working for quite a few operating hours.-with only a fewchanges to it by our service technicians and your machine will be same as new.Prior to overhaul will be technical audit to determine the status of your machine,thus obtains an overview of all spare parts that are needed.

This way you can be sure that your machine lines will always operate just as effectively and efficiently as you rightfully expect along with saving a lot of your cost

General Electronics Repair and Digital Equipment Calibration

At Moz Eng. Service Ltd, we like to be transparent about what we do to your equipment, We offer updates throughout the process on the status of your devices, and we maintain a standard testing and repairing procedure for all equipment.

This procedure uses 100% true load testing and custom engineered test stands across the two main stages of the process.

Reverse Engineering to all Bottling Equipment spare parts.

For the spares which we cannot easily source within our reach, you can send us your samples and we can reverse engineer it with our original suppliers. This case is applied to spares required in both high and low quality and whose cost you want to reduce. We can reduce its cost by up to 50%.

Our Testimonials

Success Stories

We have been working with MOZ Engineering Services Ltd, and their commitment to delivering high-quality engineering solutions has been exceptional. Their expertise in plant maintenance and parts procurement has drastically improved our production efficiency. The team is knowledgeable, responsive, and dedicated to ensuring that every project is a success.

Jermainel P.

MOZ Engineering has been a reliable partner for our engineering and maintenance needs. Their project management skills are unparalleled, ensuring that all timelines and budgets are met without compromising on quality. Their ability to reverse-engineer complex components has saved us both time and costs on several occasions. Highly recommended!

Chris W.

The team at MOZ Engineering Services Ltd has provided top-tier maintenance for our conveyor systems. Their attention to detail and proactive approach to preventative maintenance has reduced our downtime significantly. It’s clear they prioritize their clients’ success, and we are extremely pleased with the results.

Gregory U.

Frequently Asked Questions

FAQ's

What industries do you serve?

+How do you ensure the quality of the parts you supply?

+What is your approach to project management?

+Do you offer ongoing maintenance services?

+How do I get started with your services?

+© 2024 MOZ ENGINEERING SERVICES LTD. All Rights Reserved.